Automotive Gasoline Combustion Power Performance Quantitative Analysis Test Platform

Instrument design background

With the diversification of sources and blending technologies of automotive gasoline, the differences in the components of automotive gasoline with the same brand but different sources are also increasing. As a result, the quality of combustion power generation varies, and currently, there is still a lack of inspection, testing, and measurement standards for the combustion power generation of automotive gasoline.

This has caused many car gasoline products to meet ASTM or national standards, but there is a problem of gasoline being "not burn resistant" in actual use by car owners, and it is also difficult to control and supervise the quality differences in the actual application of car gasoline, seriously affecting consumer rights.

It has great guiding significance and promoting effect on the level of oil adjustment for refineries and oil product manufacturers. Compared to different manufacturers, the higher the combustion power and durability of the gasoline produced for vehicles, the better the quality of the oil, and the higher the sales volume of the oil. When retail to gas stations, the greater the refueling flow for car owners.

Instrument design background

With the diversification of sources and blending technologies of automotive gasoline, the differences in the components of automotive gasoline with the same brand but different sources are also increasing. As a result, the quality of combustion power generation varies, and currently, there is still a lack of inspection, testing, and measurement standards for the combustion power generation of automotive gasoline. This has caused many car gasoline products to meet ASTM or national standards, but there is a problem of gasoline being "not burn resistant" in actual use by car owners, and it is also difficult to control and supervise the quality differences in the actual application of car gasoline, seriously affecting consumer rights.

A quantitative indicator for evaluating the combustion power of gasoline used in vehicles is proposed, and the combustion power test of different tested gasoline used in vehicles is carried out through this equipment. Quantitative data is obtained for accurate data comparison, providing reliable basis for improving the quality of gasoline used in vehicles and driving the attention of the entire gasoline market to combustion power.

It has great guiding significance and promoting effect on the level of oil adjustment for refineries and oil product manufacturers. Compared to different manufacturers, the higher the combustion power and durability of the gasoline produced for vehicles, the better the quality of the oil, and the higher the sales volume of the oil. When retail to gas stations, the greater the refueling flow for car owners.

Instrument Overview

1. Instrument composition

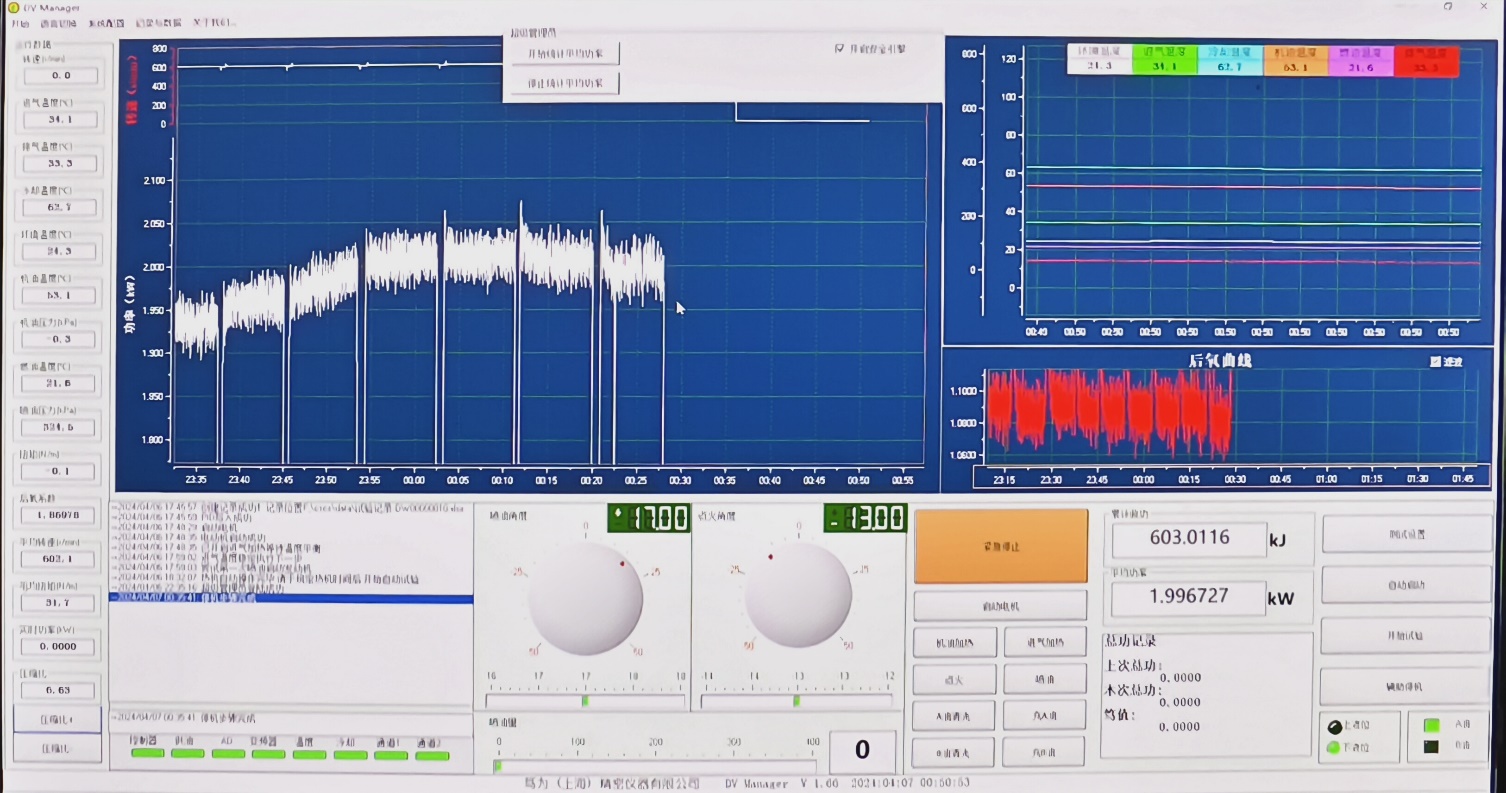

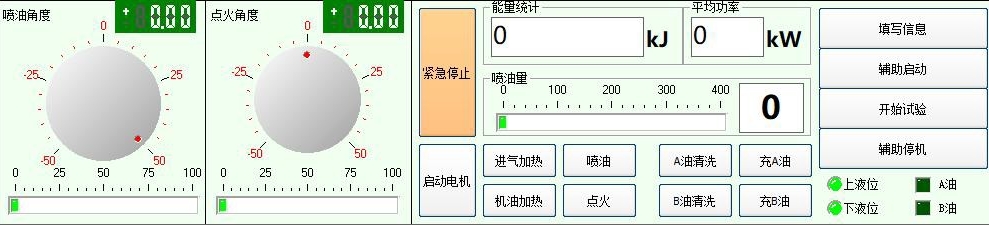

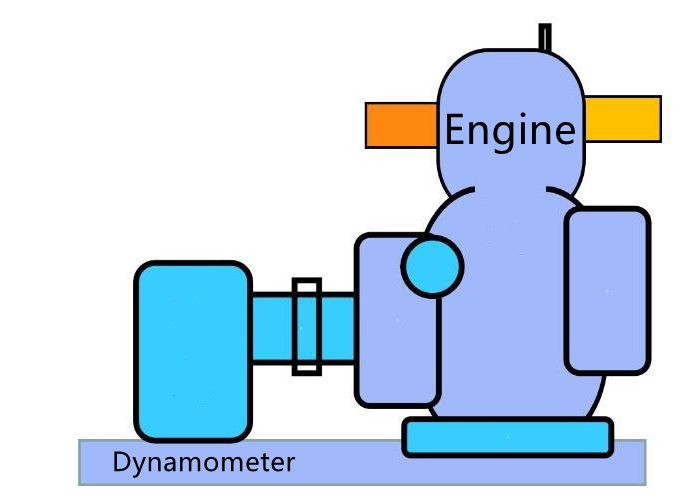

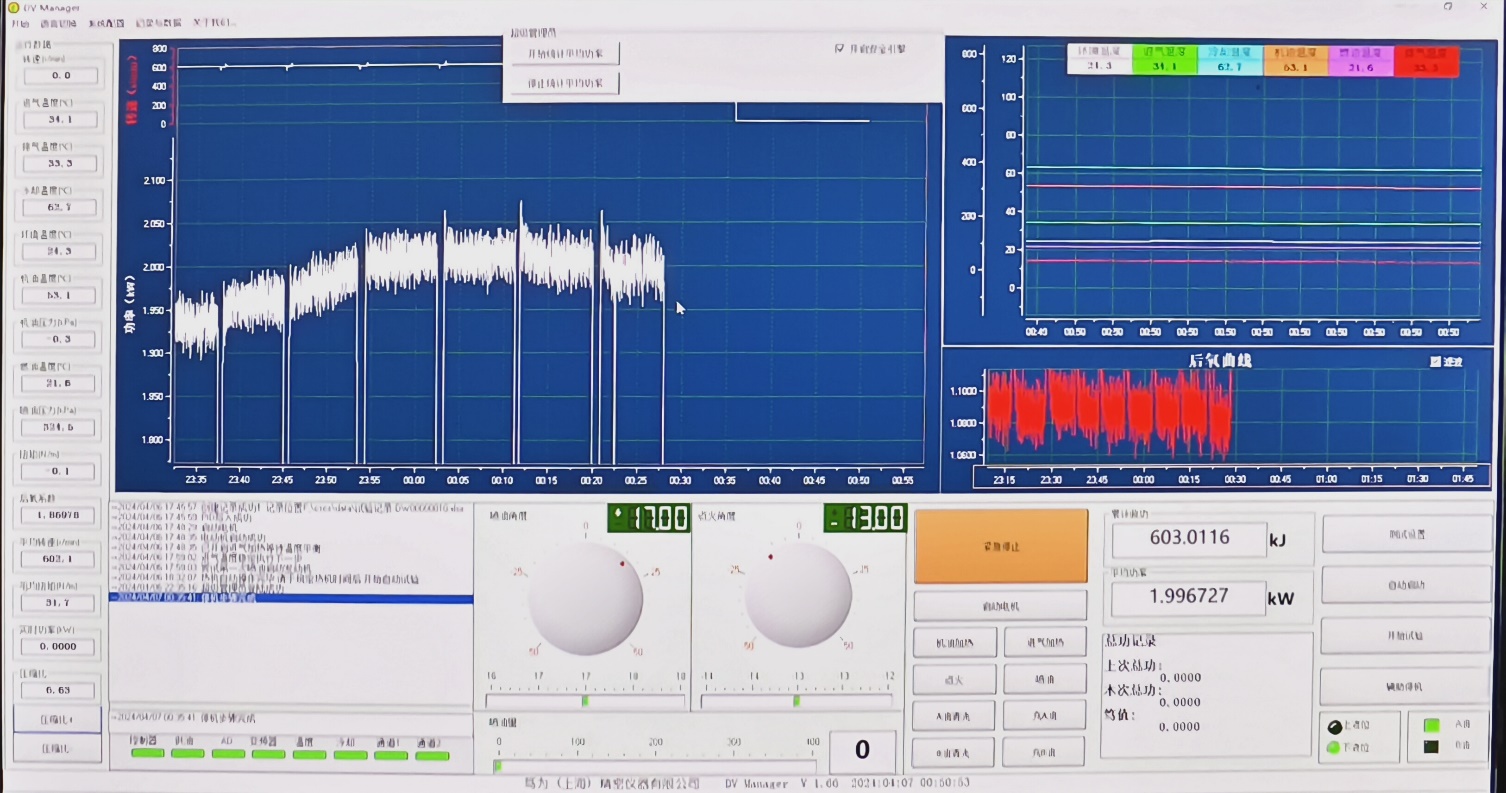

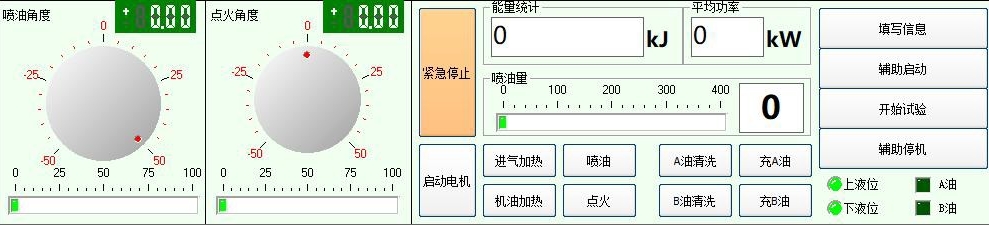

The main body of the instrument consists of a constant speed single cylinder four stroke variable compression ratio internal combustion engine, a fuel energy conversion output unit, a constant exhaust cooling cycle system, an intake treatment system, an emission system, a measurement and control system, a software real-time control system, a power quantification analysis system, and a fully automatic tracking system for the computer.

2. Summary of Test Methods

Test the power performance of gasoline combustion in vehicles, conduct quantitative analysis, and use standard test engines to burn and operate under specified operating conditions. Compare the total amount of work done by sequentially burning the sample fuel with an equal amount of standard sample of the same brand. Comparison of fuel combustion performance.

3. Elements in experimental methods

They are standard substances, testing equipment, and testing conditions.

The experimental method has already clarified that this is a comparative test, which is a comparison between the sample fuel and the standard substance, only relying on the experimental comparison of the equipment. As long as the testing equipment remains stable, the working conditions are within the normal range, and the quantity is equal, it is sufficient.

Simply put, the experimental equipment is a balance, and the standard substance is a weight. The comparison of work ability between sample fuel and standard substance under standard operating conditions through testing equipment is like weighing sample fuel with weights, which can obtain quantitative data and visually display it.

4. Test conditions

The testing of the sample is based on the gasoline grade, and the operating conditions should be maintained as continuous as possible throughout the entire testing process, that is, the consistency of the operating conditions during the determination of the gasoline grade should be maintained as much as possible. And these operating parameters have also been verified through long-term experiments in the early stage, which will not cause variations in gasoline grades.

Conceptual confusion and misconceptions that can easily arise

What is the assessment of "fuel consumption per 100 kilometers"?

The assessment of fuel consumption per 100 kilometers is based on the specific fuel consumption performance of the vehicle (or engine), not on gasoline fuel, but on two different types of tested objects.

The device measures the fuel - "gasoline for vehicles", not the vehicle or its engine, but rather uses the engine as a testing tool.

What is the "calorific value" of fuel?

The heat released by complete combustion of a fuel is called its calorific value. The essence of this principle and test method is the ability of the fuel to fully convert into external work, the output of work, quantitative analysis, and quantification. It can be extended to the degree of energy generated by the fuel after combustion. However, "calorific value" cannot fully express the original intention of this experiment.