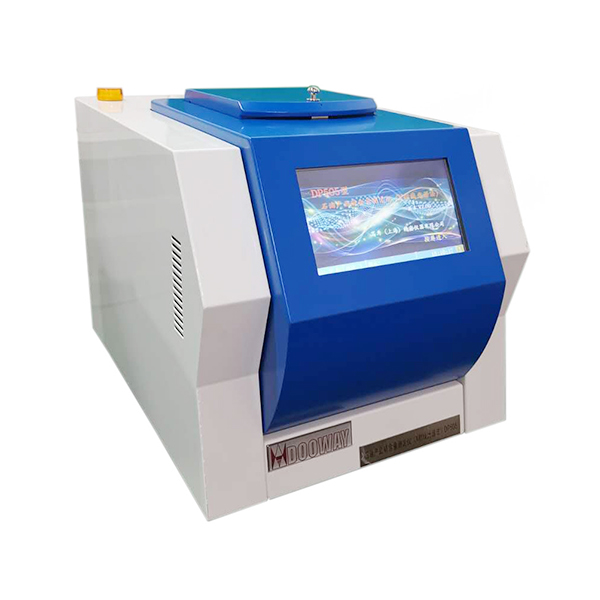

Sulfur Content Of Petroleum Product Tester

- DOOWAY

- CHINA

- 30 days

- 30 sets per month

Overview

Determination of sulfur and chlorine content in products (X-ray spectrometry) the trace sulfur content of petroleum products was determined according to the standard: ASTM D4294, and the trace chlorine content of petroleum products was determined according to the standard SH/T0161, ASTM D4929line ASTM D7536 and ISO 15597.

Because it adopts physical analysis method, it has the characteristics of fast analysis speed, no complex sample pretreatment, high precision, small human error, low labor intensity of operators, no pollution and so on.

Therefore, it has been widely used in the world and basically replaced other analytical methods for sulfur determination.

Sulfur Content Of Petroleum Product Tester Instrument features:

1. Adopt the brand-new touch screen color liquid crystal display screen, which has superior control performance. The newly designed multi-channel pulse amplitude analyzer based on CPLD,FPGA,DSP technology is used to replace the original simple multi-channel pulse amplitude analyzer, which greatly improves the long-term stability of the instrument.

2. Rapid analysis: generally, the content results are given in tens of seconds. Automatic Chand H ratio correction: suitable for a variety of samples.

3. Absolute determination: the interference of hydrogenated gasoline and diesel background is removed effectively, and the data are almost consistent with the combustion method, and a variety of calculation methods are selected to overcome the measurement error caused by the inconsistency between the fuel oil matrix and the standard sample matrix.

4. Automatic curve selection: direct measurement, the instrument will automatically select the curve suitable for the sample in the measurement, and there is no need to change the curve in the measurement process.

5. Automatic spectrum stabilization function: avoid energy spectrum drift caused by temperature change and internal attenuation of the detector. The long-term stability and accuracy of the instrument are guaranteed. Calibrate less than twice a year.

6. Self-tuning device: self-calibration is carried out before the instrument analyzes the sample to ensure that the instrument is consistent with the calibration state of the instrument and reduce the problems of instrument instability.

7, deviation correction: put in the standard sample, one key operation can repair the error of the curve.

8, powerful storage function, can store 1000 measurement data, easy to query at any time.

9. Built-in detector: reduce physical damage. The failure rate is extremely low.

10. X-ray protection: strict X-ray protection ensures the safety of operators.

Sulfur Content Of Petroleum Product Tester Technical Specifications:

1. Analysis range: the analysis range of S and CL can be adjusted, which is selected by the method of calibrating the working curve.

2. X-ray tube: voltage: ≤ 50keV, current: ≤ 2mA, power ≤ 50W, target: Ag.

3. Detector: SDD, effective area: 20mm2, resolution: ≥ 123eV, counting rate: ≤ 2Mcps, incident window: 8 μ m beryllium.

4. The detection limit is 0.1ppm, 0.18ppm.

5. Linear error analysis accuracy: measuring S: it meets the relevant requirements of GB/T 11140, ISO20884, ASTM D2622, D7039, D7220 and so on. Test Cl: it meets the related requirements of ASTM D4929Magi ASTM D7536 ISO 15597 and so on.

6. System analysis time: 1mm 999s, recommended value: micro measurement is 300s, constant measurement is 60s inherent error, analysis accuracy: for example, petroleum: execute standard GB/T 17040, GB/T17606, ASTM4294.

7. System analysis time: 30, 60, 100, 150, 300 seconds, the recommended value is 100 seconds.

8. Conditions of use: ambient temperature: 5 ℃ to 40 ℃, relative humidity: ≤ 85% (30 ℃), power supply: 220V ±20V, 50Hz.

9. Power consumption of the whole machine: < 150W.