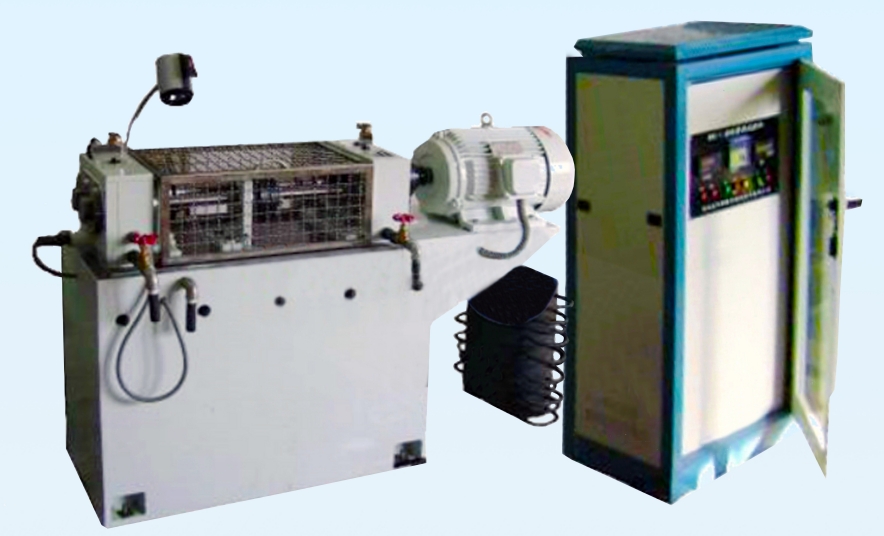

Gear Wear Testing Machine DP801

- DOOWAY

- CHINA

- 30 days

- 5 sets per month

Equipment use

Determine the gear scratch load and weight changes caused by gear oil using the West German lubrication test (DIN51354) standard method, namely the FZG gear oil test; Determine the strength curve of the tooth surface bearing capacity of gears made of different materials; Determine the strength curve of the root bearing capacity of gears made of different materials. Fatigue strength test of tooth surface. Testing method for shear stability of lubricating oil.

Applicable standards

ISO 14635-1-2000 Gears FZG test procedures Part 1 : FZG test method A/8,3/90 for relative scuffing load-carrying capacity of oils

DIN 51354-1:1990 Lubricant Testing FZG Gear Test Bench General Working Principle

DIN 51354-2 Pruefung von Schmierstoffen; FZG-Zahnrad-Verspannungs-Pruefmaschine; Pruefverfahren A/8,3/90 fuer Schmieroele

ASTM D5182-19 Standard Test Method for Evaluating the Scuffing Load Capacity of Oils (FZG Visual Method)

Technical parameters

No | Product performance | Technical parameter |

1 | Maximum torque | 1000N. m |

2 | Spindle motor | Dual speed motor |

3 | Speed | 1440r/min, 2880r/min |

4 | Control oil temperature | Room temperature -90℃ |

5 | Tooth surface temperature detection | room temperature~260 ℃ |

6 | Lubrication methods | immersion and circulating oil lubrication |

7 | Sample size | Standard gear |

8 | Test space | Meet and facilitate the clamping of friction pairs |

9 | Shutdown control mode | manual/automatic (time, friction, etc.) |